Work Cell Design and Implementation Services

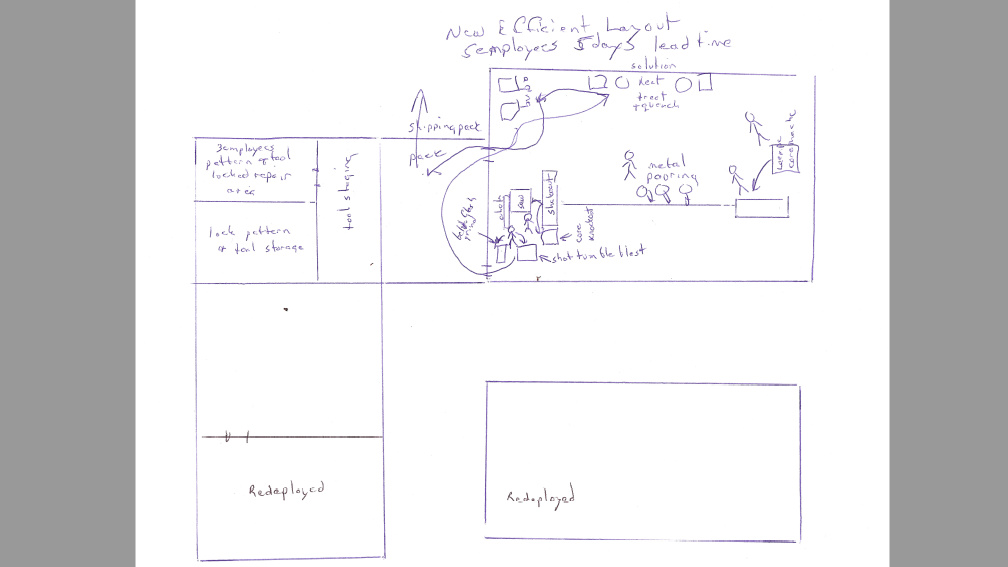

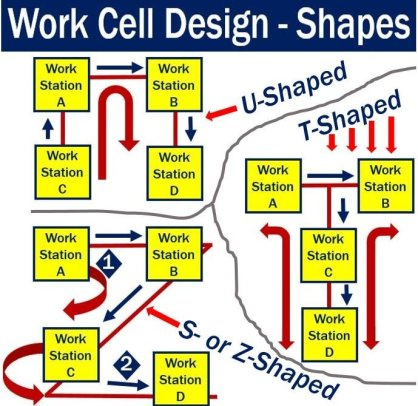

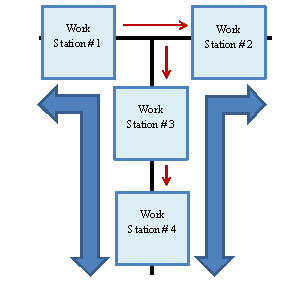

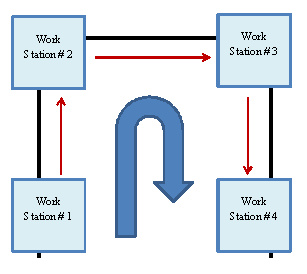

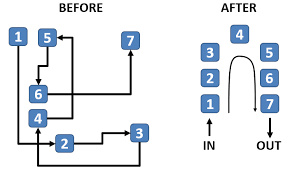

Burns Bridge has over 25 years experience with work cell design and implementation. Burns Bridge can help you with your efficiency improvement needs. Burns Bridge understands when and how to link successive processes together to achieve quantum improvements in throughput, lead time, quality and bottom line using work cells capable of flexing to meet demand. Whether it is a straight line, tee or U shaped work cell, Burns Bridge has a practical understanding of work cells and can help you with practical low cost solutions to your process design and improvement needs.

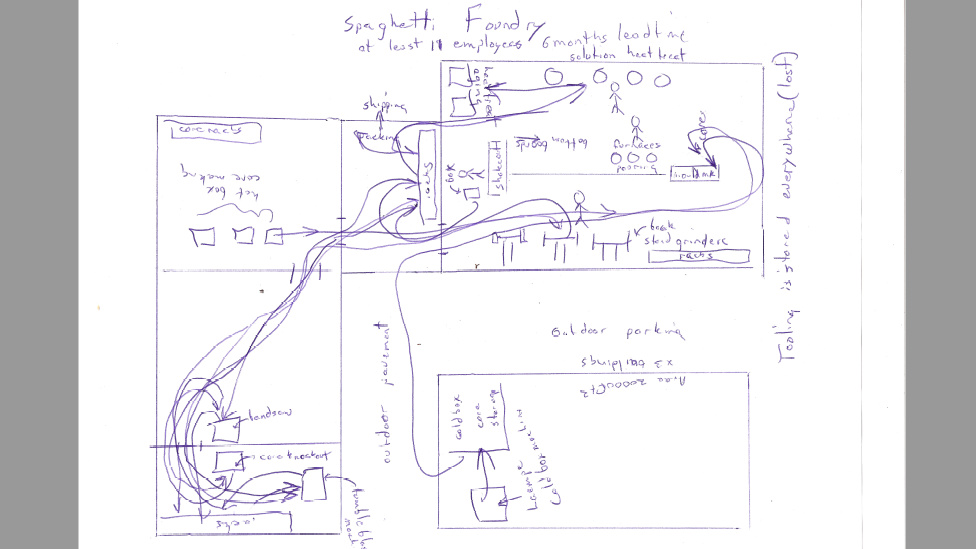

As an example, in a jobbing aluminum foundry, over a five year period, Burns Bridge using work cells, achieved a two thirds labour reduction, a doubling of throughput, a 50% reduction in floor space, a 95% lead time reduction, and a 90% reduction in internal scrap by implementing work cell manufacturing and addressing a number of process quality problems. As an additional example, Burns Bridge implemented a small dedicated work cell to streamline bearing frame assembly in an engineered pump plant reducing labour by over 80%.

Work cells are a powerful and effective way to improve productivity.

Home

Home