Pre-start Safety Reviews

As of October 7, 2000 Section 7 of the Ontario regulation for industrial establishments, there is a requirement to perform a pre-start safety review for process changes made to an industrial establishment. Such reviews when required by the regulation must be completed by a professional engineer. The following changes may trigger a review:

- A process uses or produces a substance which may result in worker exposure in excess of specified allowable limits.

- Flammable liquids are stored or will be dispensed in a room.

- A dust collector which may involve an explosive risk is being installed.

- A factory or process produces aluminum or steel or will be a foundry or foundry process.

- Safeguarding devices that stop a process or interlocked barrier guards are used.

- A racking or storage structure is being installed or modified.

- An explosive hazard is being installed which could impose an imminent risk.

- A lifting device, travelling crane or automobile hoist is being installed.

Case Example: Light Curtains versus Two Hand Controls

Background: After completing pre-start safety training in a Tier 1 automotive fuel and brake bundle fabrication assembly and test plant in early 2003 engineering staff had acquired detailed knowledge on automated safety devices needed to protect employees running semi-automated leak testing equipment. The plant cut end formed and bent fuel tubing to which were added hoses and tubes using crimping and insertion processes. After lines were pre-assembled they were bundled and placed in a nest in a leak tester. The leak test process was initiated using either twin palm buttons or twin capacitive sensors to protect one employee.

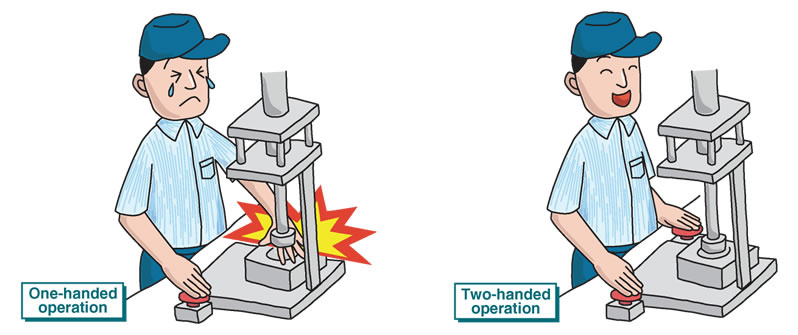

Problem: The plant had a small epidemic of minor pinching injuries associated with the operation of the leak testers in the plant. It became evident that supervision would add one or more employees to assist with the leak tester operation due to a number of physical deficiencies with the nest tooling and end point loading. With only two palm buttons to protect one employee, the second employee was prone to injury due to hands being in the wrong place when the leak test cycle was initiated by the first employee.

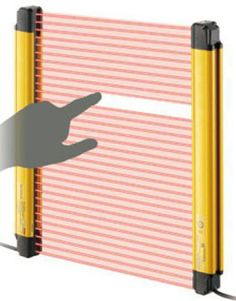

Solution: A decision was made to replace all of the two hand controls with light curtains and to guard the sides of the leak testers to make it impossible for an employee to have a hand o finger inside the energy envelope at time of cycle initiation or after cycle initiation.

Outcome: The pinching injuries were completely eliminated at a cost of about $3000 per leak tester. With the safety problem arrested, engineering staff worked diligently with maintenance skilled trades to systematically eliminate all leak tester deficiencies associated with every leak tester achieving an approximately doubling of labour productivity. Engineering used the knowledge gleaned from this experience to rewrite equipment procurement specifications to add light curtains, fixed guards and interlocked guards needed to prevent and eliminate all employee injuries.

In the solution below, employees working at small press stations are protection from pinch hazards by a light curtain. Capacitive cycle two activation swipes are still used to initiate the process cycle.

Finally there are ergonomic soft tissue injury issues such as carpal tunnel and or bilateral tendonitis related to the long term repetitive use of two hand control palm buttons which should rule out there use in most cases. With a combination capacitive swipe light curtain shield the employee may use either or both hands to initiate the process cycle.

Home

Home