Natural Gas Combustion Systems

Burns Bridge has 19 years of natural gas combustion system troubleshooting and maintenance experience in the following industries:

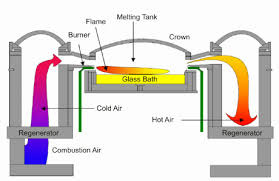

1. Burns Bridge spent the first four years of a ten year tenure in a glass container moulding plant processing 600 tons of sand in glass containers, coaching and training maintenance trades how to recognize and correct a host of deficiencies on a total of almost 100 separate burner systems. Burner flame outs decreased from hourly to more than six months between failures. Burns Bridge is familiar with thermocouples, optical pyrometers, gas safety shutoff valves, gas pressure regulator sizing, control valve sizing, pressure switch location and sizing, combustion fan sizing, computer based process controllers and single loop PID controllers as well as numerous other issues related to the safety and reliable combustion of natural gas.

2. Burns Bridge expanded on the above experience through another 5 years of experience in an aluminum foundry which used natural gas fired furnaces to melt and hold metal. Through this period there was an 80% reduction in the number of furnaces used and a more than 85% reduction in the cost of natural gas used per pound of metal shipped. Through this period Burns Bridge coached subordinate engineers to design build and install a gas fired liquid metal launder and a central aluminum shaft melting furnace for a small aluminum die cast plant. As a further innovation natural combustion systems were retrofitted to convert two electric solution heat treat furnaces to gas. In the same installation unheated solution heat treatment water quench tanks were retrofitted with natural gas heaters to keep the water at the required temperature eliminating cracked castings caused by quenching with cold water.

3. In an automotive OEM piston casting cell, Burns Bridge reduced the refractory maintenance spend on melting and holding furnaces from $250000 to $25000 per annum.

Burns Bridge is comfortable troubleshooting PIV computer control loops, single loop PIV and on-off single loop controllers related to wide spectrum of natural gas burning appliances..

Home

Home