Error proofing

Error Proofing Background and Benefits: In North America this concept prior to the 1990's was popularly called "idiot proofing". However  Deming's tenure in Japan in the 50's and 60's initiated a revolution in manufacturing management and quality improvement. In 1982 he published Quality Productivity and Competitive Position. Deming articulated the 7 deadly sins of management and the fourteen principles for improving excellence in an organization. The third principle espoused the need to cease reliance on inspection and to build product quality in. This method became known as error proofing and in Japan, Poka Yoke. The term idiot proofing is derogatory and demeaning and is no longer in common use.

Deming's tenure in Japan in the 50's and 60's initiated a revolution in manufacturing management and quality improvement. In 1982 he published Quality Productivity and Competitive Position. Deming articulated the 7 deadly sins of management and the fourteen principles for improving excellence in an organization. The third principle espoused the need to cease reliance on inspection and to build product quality in. This method became known as error proofing and in Japan, Poka Yoke. The term idiot proofing is derogatory and demeaning and is no longer in common use.

Shigio Shingo's book  Zero Quality Control: Source Inspection and the Poka Yoke System in the preface neatly summarizes the main benefit of error proofing. Plants having poorly or non-error proofed processes will have 6-10% process discount (scrap is but one example) on a good day. In contrast, a well error proofed factory will have 2% maximum scrap on a bad day. Clearly there is a huge financial and morale benefit to error proofing. Employees consistently abhor making bad parts.

Zero Quality Control: Source Inspection and the Poka Yoke System in the preface neatly summarizes the main benefit of error proofing. Plants having poorly or non-error proofed processes will have 6-10% process discount (scrap is but one example) on a good day. In contrast, a well error proofed factory will have 2% maximum scrap on a bad day. Clearly there is a huge financial and morale benefit to error proofing. Employees consistently abhor making bad parts.

Employees are error prone and will make mistakes even when highly motivated. Statistical studies have found over and over that, in any human controlled process, mistakes will occur up to 15% of the time. Due to this problem, where there are no error proofs available, the only way to prevent errors is to add multiple layers of inspection until the error rate drops to an acceptable level. Today, customers are highly sensitive to errors, and quality reputations can be ruined within days, due to the high speed at which bad news is disseminated on the internet. As a result, the new normal today, is zero defects in every operation including those which are service based.

The following few case examples are provided of error proofs in various processes:

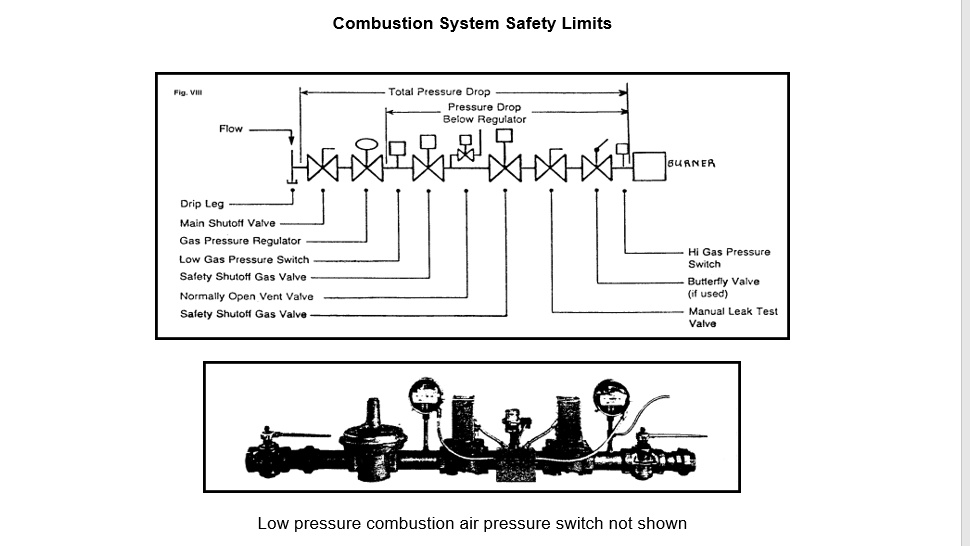

Combustion systems,

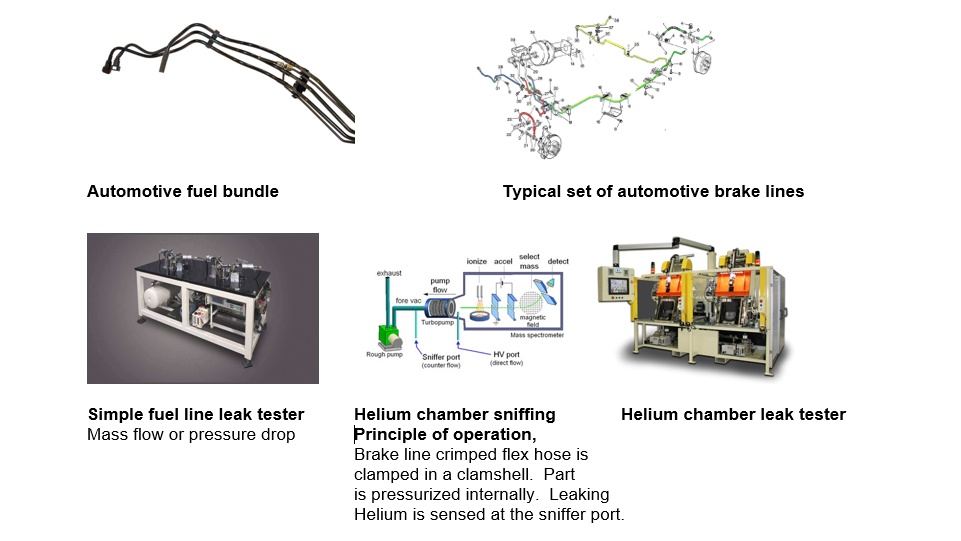

Automotive Tier 1 fuel and brake bundle fabrication plant,

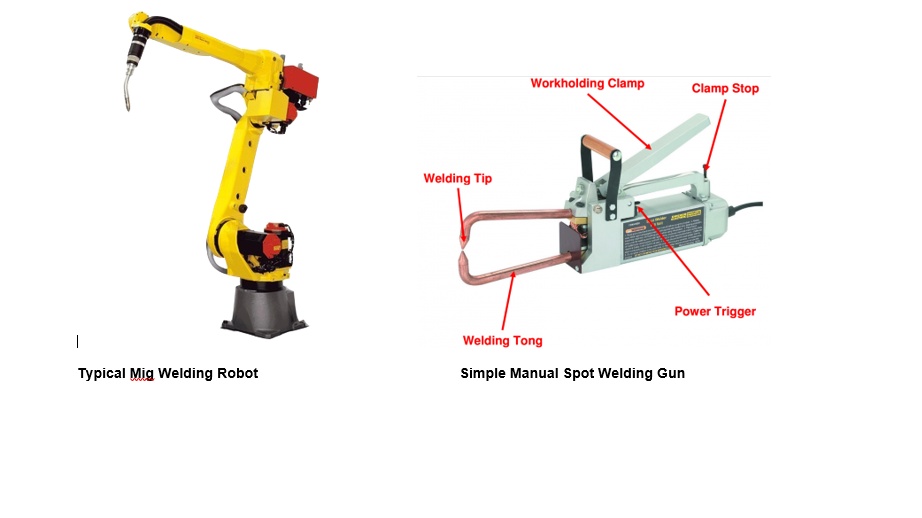

Programmable logic controller programming on a spot welder

Service repair business.

Combustion Systems: The above graphic illustrates a typical gas train for small industrial natural gas combustion systems. The combustion air, low pressure gas and high pressure gas switches prevent an operator from opening the safety shutoff value if the appropriate pressures are not sensed. Further a fault in either gas pressure or combustion air pressure will automatically close the safety shutoff valve turning off the burners and avoiding an "explosive" condition.

A bottle plant in the early 1980's had a host of reliability problems (errors) with their burner systems, and was incurring unacceptable amounts of downtime and had a pack rate of 50-55%. As a result of the low pack rate, defective bottles were leaking to customers in every shipment.

To address this problem the process engineer at the time trained process technicians how to trouble shoot and repair burner systems. After a couple of days of training, the time it took to troubleshoot or control loop having a burner dropped from weeks to under one hour. There were a host of mechanical deficiencies which had to be addressed as follows:

Air filters were installed on combustion fans to stop dirt infiltration.

Combustion fans were replaced by higher pressure units to improve system turn down and temperature control.

Gas pressures were raised on all gas trains to 15-20% above the combustion air blower rated pressure to achieve stoichiometric ratios at low and high fire. Springs were changed in almost all line and group pressure regulators.

Low gas pressure switches were moved to the upstream side of the safety shutoff valve.

High gas pressure switches were moved to the downstream side of the safety shutoff valves.

Combustion air pressure switches were added where there were none present.

A number of control thermocouples were relocated to better positions away from the burner flames to stop process toggling.

Tier 1 Automotive Fuel and Brake Line Fabrication Plant: In the early 2000's a Toronto area plant having an already very low internal scrap rate of less than 2%, needed to improve its parts defective to zero parts per million. To achieve this goal, the engineering manager, arranged leak tester sensor training on all types of sensors (helium mass spectrometry, pressure drop and mass flow) for engineering, quality and maintenance technicians. After completing this training a concerted group effort was made to eliminate errors in the shop. The following items were completed or implemented:

To prevent pinching injuries, all leak tester two hand controls were replaced with light curtains. Interlocked guard switches were installed on dedicated bender guards.

To prevent fouling of process verification orifices from daily use, small sub-micron filters were purchased to protect the orifices from dirty compressed air.

To eliminate first time through test failures on the leak testers (initially running at 35-50%), a host of improvements were made to the endpoint fixturing to set the part volume. These improvements reduced the first time through failure rate to zero.

To prevent employee errors at bending insertion, and crimping, an assortment of error proofs were added to the tooling nests to prevent an employee from setting the wrong part, cycling the process without a part, or cycling the process with the wrong part orientation and other failure modes.

To eliminate a long term dysfunctional brake line test problem due to the use of red herrings, proper verification orifices were purchased and the equipment modified to allow their use to verify the process efficacy hourly. With other adjustments, the "bad test" problem was converted to a "good test" in half the time.

Central to the success was upfront training of all engineering and maintenance staff on the leak test sensors and how they worked by three separate OEM vendors.

PLC programming error proofing: A semi-automatic spot welder in a highly automated tier 1 stamping and robotic weld assembly plant had a problem with cold weld nuggets. The machine processed two stamping assemblies at a time making two spot welds on each assembly. Part presence sensors proved part presence and table position prior to spot weld gun closure and weld cycle initiation. On average the machine had deteriorated to the point where there was one or more of four cold welds per cycle of the machine. In addition there was a large amount of weld expulsion with forced the operators to wear protective gear (vests, protective sleeves, goggles etc.).

The maintenance manager with a small group of key employees, after observation of the process for an hour concluded that the guns might be opening while the power was still on. A PLC programming specialist was engaged to assess the code being used to initiate and control the weld power supply. It was found that the valve outputs controlling the guns down and other portions of the cycle were not being latched once the cycle start limits were made (part presence sensors). The large amount of pressure caused by the weld guns to clamp the parts being spot welded together with the heat produced from the welding process would result in modest part flexure which could result in a loss of part presence sensors. In any of these conditions the guns could open while the current was on pulling an arc, creating a cold weld and spraying the employee with expelled metal.

A new program was written at a cost of less than $5000 to latch the outputs and eliminate these and other failure modes.

Outcome: The weld expulsion problem was completely eliminated. Other than a face shield and safety glasses employees no longer had to wear any additional shielding clothing. The cold weld problem was eliminated and the process proceeded to run for months without a defective spot weld being made. The knowledge gained here with regard to process control related to machine motion and weld power supply initiation was implemented on numerous other spot weld cells where expulsion was also a problem.

Service Repair Shops: A service repair shop is much more difficult to error proof because of the variation in product repaired and the one piece order quantity. The above shop is a typical example of a rotating equipment repair entity. The following error proof items are considered essential to the successful operation of such an entity:

100% inspection system of all third party and internally produced parts.

A document system which provides shop employees with a piece of equipment specific set of documents for inspection, repair and final inspection.

Highly skilled trades (generally red seal skilled trades in the top 20% of the class)

Disassembly and final assembly procedures for each piece of equipment.

Assembly specific check lists.