Automotive Tier 1 Stamping Shop - Bottleneck Easement Press Shop Examples

Situation: A stamping and welding plant consisting of 150000 square feet, 350 employees had a number of internal throughput bottlenecks which resulted in a delivery record of 97%. In automotive tier 1 manufacturing; the expected minimum metric is 99.99%. The plant was incurring $70000 per month in premium freight.

The plant contained 10 side frame presses ranging in size from 400 to 2000 tons. The majority of the presses were coil end fed but could be configured differently based on the product. The welding shop contained 50 robots with 25 performing mig welding and 25 units spot welding.

The plant suffered from the following problems:

Press shop up time of 18-25%. A well running press shop will run at 85 to 90% up time.

Excessively long change over times of up to two days. Keeping in mind that some shops change their presses in minutes, a 4 hour changeover for this shop would be considered acceptable.

An epidemic of smashed stamping dies which resulted in a tool room running chronically 100% over budget.

Weld shop rework in excess of 60% in an industry where 2% on a bad day is considered acceptable.

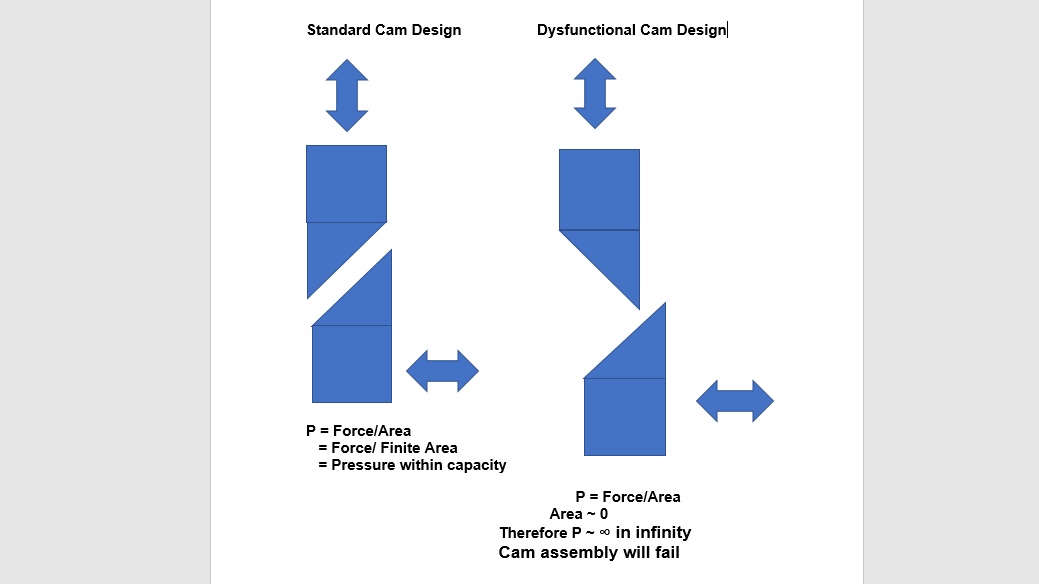

Case 2 Analysis: The die was opened in the tool room and the cam design reviewed. The above sketch, left hand view, shows a properly designed cam set. The problem tool possessed cams as per the right hand arrangement. With the upper cam backwards a point contact area is created having an extremely small effective area of action constructively creating an infinite stress at the point of contact. With this arrangement the cam set would fail after a few dozen strokes. This was a "design build" error by the tooling vendor. The die was returned for warranty repair. Tool makers failed to see this design flaw due to the visual presentation of the cams when the die is open (ram portion flipped upside down) made the cam set look like the left hand arrangement in the figure above.

Outcome: The die after modifications to have cam sets revised, proceeded to run without incident. This was considered the second worst reliability issue in the press shop.

Within a few months of implementing a die protection program and installing end of strip sensors on the majority of stamping tools, the tool room was running under budget for the first time in the 15 year history of the plant. This savings amounted to over $75000 per month. Press shop up time improved substantially along with employee morale.

Other improvements implemented:

A rudimentary quick die change program reduced changeovers to about 8 hours from at least 24.

A centralized die lubrication automated die lubrication system was installed. The automatic lubrication system had biocide addition and precise water lubrication mix control as well as alarms to indicate low liquid alarm conditions.

Die lubrication systems were installed on the majority of the presses which reduced die lubrication consumption by over 90%. The plant was spending 30k per month in liquid waste disposal charges to pump out the basement the bulk of which was die lubrication fluid. With the installation of this system a 90% reduction in pumping costs would have been realized.

Press up time started to approach 60%, a 2.5x improvement in up time.

Most importantly, the press shop ceased to be a delivery bottleneck.

Home

Home