Assembly Process Solutions

Burns Bridge's principal has almost 15 years of assembly and test process experience gained in four different industries as follows:

- Automotive OEM engine assembly,

- Automotive tier 1 manufacturing fuel and brake bundle assembly and test,

- Hydraulic Institute Engineered pump OEM manufacture assembly and test,

- Repairs of high energy OEM API pumps, and

- Third party rotating equipment repairs (pumps, fans, rotary lobe blowers, steam turbines etc.)

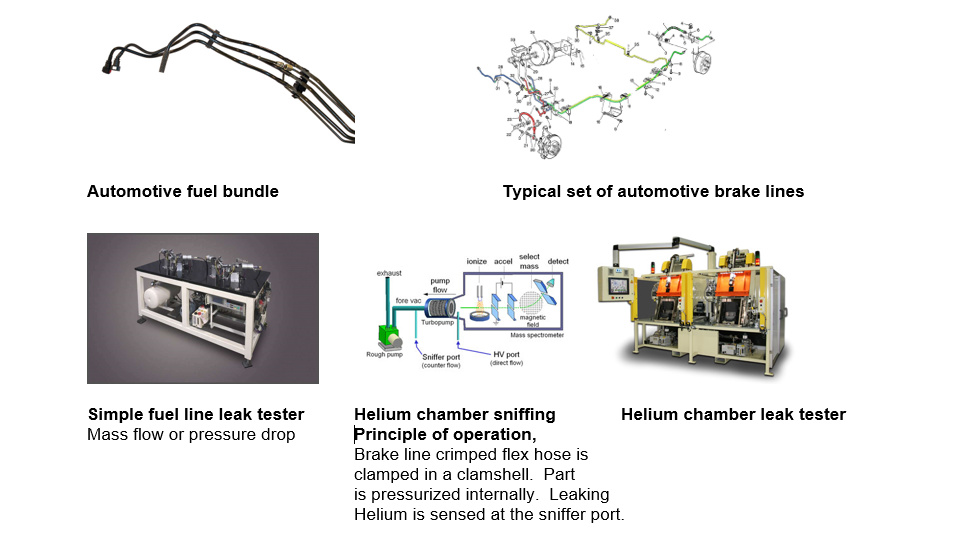

Burns Bridge has experience with torque processes in automotive engine assembly and original equipment manufacture pump assembly, hydro-testing of pump components and sub-assemblies, underwater, mass, and pressure drop fuel bundle assembly leak testing, helium mass spectrometry testing of brake bundles, ergonomic solutions, material handling solutions, work cell manufacturing, high energy testing of pumps together with many other items associated with assembly processes.

As an example, an engineered pump manufacturing plant had a competitiveness problem with pricing on a family of horizontal suction top centre discharge pumps. To make assembly of the bearing frame sub-assembly much more efficient, Burns Bridge coached an engineering student to specify and procure simple equipment (two bearing heaters, rotating element bearing cooling compartment, pump shaft part manipulator and a locked shadow board hand tool cabinet, with a powered electric torque wrench) in four months. A more than 80% labour savings was achieved.

The same shop was building an average pump, 3-4 times and testing it as many times at great expense and inefficiency. Over a three year period a wide assortment of component machining and assembly process problems were found and eliminated. As a final outcome, the average pump was built once and tested once for a minimum two thirds labour savings. Employee morale improved as each item of frustration and waste was eliminated.

Finally, in a automotive tier 1 fuel bundle plant coaching a group of engineers and maintenance workers, Burns Bridge achieved a 300% increase in the speed of the final assembly and test process (leak testers). Having increased the bottleneck speed, the plant was able to maintain best of 17 facilities profitability through a challenging financial period.

Burns Bridge can help you with the majority of your assembly and test problems.

0

Home

Home